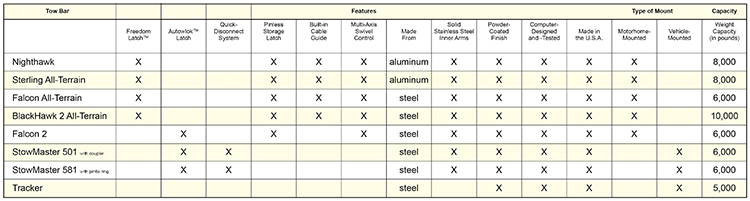

|

Our exclusive Autowlok™ locking system, a patented storage latch and ROADMASTER's well-deserved reputation for reliability are all built-in features on the Falcon 2.

For most RV towing combinations, we recommend our premium tow bar line,

which offers exclusive features to enhance your towing experience.

• One-person quick-connect and disconnect

At the towed vehicle…

Thanks to an exclusive, self-supporting quick-disconnect system, one person can easily connect or disconnect the Falcon 2 in seconds. (These baseplates also make it extremely easy to attach accessories such as the

Guardian™, Stowaway and the Tow Defender).

And at the motorhome…

Telescoping, independently-adjustable inner arms are easy to maneuver into position. Simply pin them in place and then drive your motorhome away and the arms automatically center and lock in place.

• The largest hook-up radius in the industry means you don’t waste time lining up your towed vehicle. You can’t say this about many things in life but connecting the Falcon 2 is just like horseshoes — “close” is good enough!

• Self-lubricating nylon bushings eliminate friction between the inner and outer arms for smooth, easy operation. Other tow bars have steel riding on steel.

• Autowlok locking mechanism

This mechanism is so reliable and safe that it's been used since 1984 on more than 250,000 Falcon and StowMaster™ tow bars.

• Motorhome-mounted

When you reach your destination, the Falcon 2 conveniently stores out of the way on the back of the motorhome.

• Solid stainless steel inner arms

Solid stainless steel inner arms for smooth, trouble-free operation and easy maintenance. Stainless steel looks better, lasts longer and prevents corrosion that binds — ROADMASTER tow bars are the most rust-free in the industry.

• A lustrous, high-tech powder coat finish for maximum durability. This finish exceeds all 500-hour salt spray, high-impact and extreme weather standards. In this process, charged particles of pigment are sprayed onto the surface of the tow bar, then baked at more than 400 degrees. The paint fuses to the metal. The result is a uniform, thick and extremely durable finish — three times stronger than solvent-based paint.

|