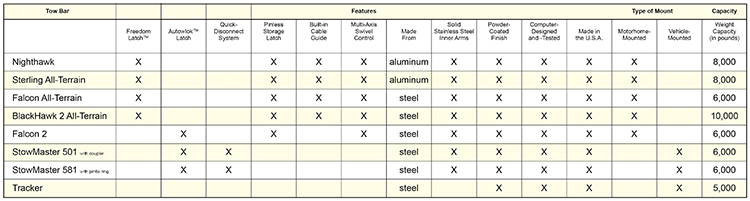

|

Nighthawk... a truly non-binding tow bar made from beautifully-styled aluminum and featuring

embedded LED lights along each arm that illuminate with the RV's lights for increased safety.

What was once the darkest portion of your towing system is now easily visible to other drivers,

and also visible when it comes time to disconnect. Includes internally-routed safety cables and power cord, solid stainless steel inner

arms and a heavy-duty 8,000 lb. capacity.

It's the first tow bar designed for Roadmaster's direct-connect baseplates, which incorporate the strength of the crossbar into the design so no crossbar is required.

Nighthawk is the next generation tow bar created and crafted from raw steel and aluminum into the

finest tow bar on the planet.

Exclusive design features:

• Non-binding Freedom Latch — easiest tow bar in the industry to use and disconnect.

• Longest tow bar arms ever produced for superior towing and stability, while providing the largest hook-up radius in the industry.

• Aluminum outer arms, solid stainless steel inner arms and baked-on powder-coat finish shield against corrosion.

• Enclosed channel for power cords and safety cables keeps things tidy, secure and protected.

• Coiled cables and power cord — you'll never need a longer version to accommodate deep drop hitches or extensions

• Nylatron bushings — eliminate metal-on-metal friction for less wear, and a smoother ride.

• Black matte finish — attractive, durable and textured for easy grip.

Order the Nighthawk today by calling our experts

at 1-800-669-9690, and then choose option 2!

|